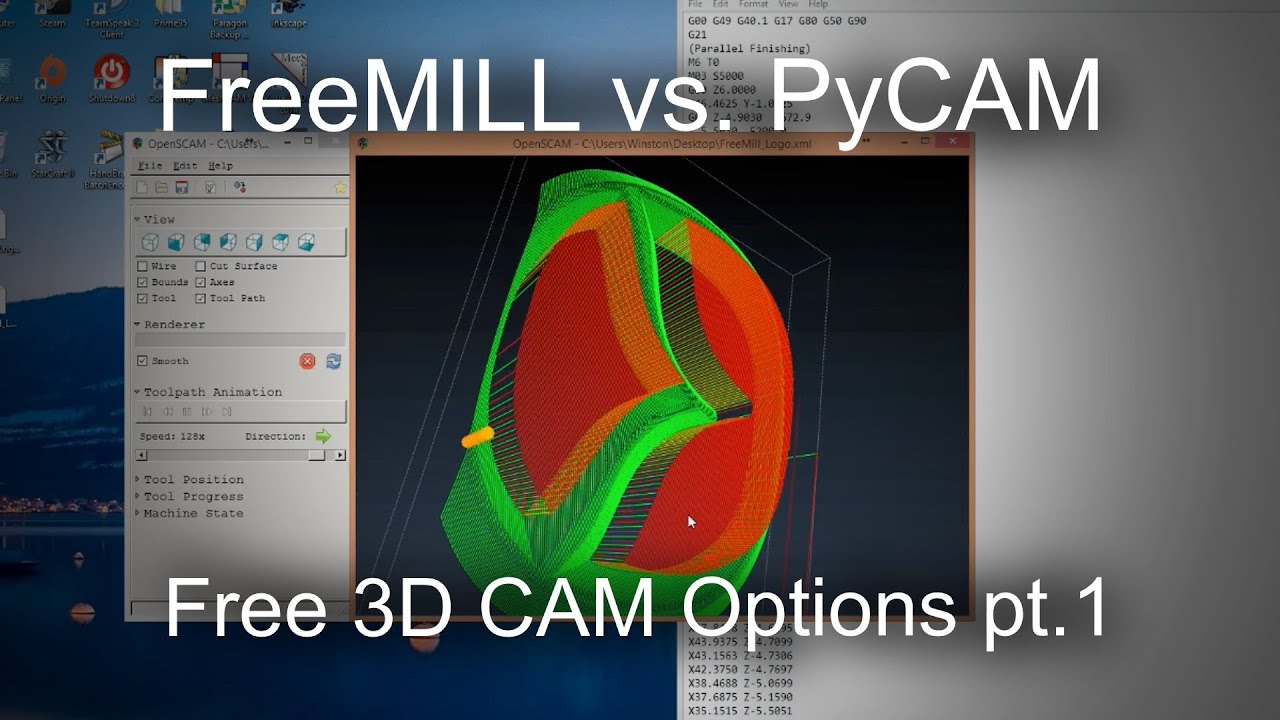

Now we get to select our stepover distance the distance between passes and generate our tool paths. I'll go into some detail on the games you can play with this setting to achieve various things later. If your part looks like it's about the right size, click next. We can also simulate the toolpaths and see what the final product might look like. Thanks for the review. After launching FreeMILL, you'll follow a wizard step by step until you generate your final toolpaths.

| Uploader: | Mikagal |

| Date Added: | 21 August 2017 |

| File Size: | 39.69 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 17135 |

| Price: | Free* [*Free Regsitration Required] |

I'll go into some detail on the games you can play with this setting to achieve various things later. Next we select the post processor and save our final output. We can also simulate the toolpaths and see what the final product might look like. A couple times running through the wizard I got some odd values on this page and the application immediately crashed when I tried to continue even thought the preview looked fine.

FreeMill (free) download Windows version

There aren't a whole lot of options here. You'll get a nice preview of the part and the determined bounds of the part and you'll be given dreemill option to specify that your part is specified in mm.

Mail will not be published required. I understand that they probably don't want to or simply can't devote resources to maintaining a free utility, but they should probably put forth a little more effort if they're hoping that that same utility is going to help sell their software. I only used the STL support since it's what my source models are in and probably the most widely used format for the hobbyist user and almost all 3D packages support it. I simply left both offsets to zero since I was going to cut the final part out by hand.

Now we set up the parting plane. As a free tool, it's annoying that it's buggy but it's still usable and worth the trouble.

Download FreeMILL

Here's some stuff that would be really nice to have but you can't really do: You can leave a responseor trackback from your own site. Leave a Reply Click here to cancel reply.

Can I change it?? Again, this is pretty straight forward, just put in the parameters of the mill you will be using. And here's the finished product: You can see that this thing is actually pretty big the outside edge of the mold is 22". Next we specify our cutting tool. I'm using a model of a ceramic mold 3e someone at the space wanted fabbed.

More bit options, only flat and corner radius mills are supported ball mills are a special case which are supported, but not V-bits Depth per pass and roughing passes can't be specified Only X or Y parallel finishing available A lot of these shortcomings can be worked through by generating additional passes manually.

This is how much bigger the piece of material you'll be cutting is than the model on either side. Here's what the generated toolpaths look like in Freemil, 3: Freemilll to Spec Making Cool Stuff.

Free Milling Software | MecSoft Corporation

Tool path generation seems pretty quick and the progress of the processor is updated in the preview window as individual passes are generated. I am always smile when I am researching something and find something by you or one the hammerspace guys.

You can use the same principal to create roughing passes with larger mills then a final detailed path with a smaller mill and smaller stepover distance.

For instance, you can't specify the maximum depth per pass, so if you've got a design that's relatively thick, the generated toolpaths will have your bit plunging all the way to the maximum Z depth of your part and then dragging through your material. It has its limitations, and it's a little buggy, but it provides a very quick and easy way to go from freekill 3D model to a physical part. You'll see this later in the preview. Next we set up our origin. You can create paths for X parallel finishing and then the Y parallel finishing on your final pass as well.

I'll be keeping an eye on the fremill and playing with it in more depth in the future.

I've successfully used dxf2gcode to generate toolpaths that I've run on machines for very simple 2. Here's some stuff that would be really nice to have but you can't really do:.

No comments:

Post a Comment